Understanding the Primary Purpose of Freight Elevators

Freight elevators are primarily used to transport heavy goods, materials, and equipment between different floors of a building in a safe, efficient, and controlled manner. Unlike passenger elevators, which are designed around comfort and aesthetics, freight elevators focus on strength, durability, and load-handling capability. They are essential in environments where large volumes of goods need to be moved vertically on a daily basis without disrupting operations or compromising safety.

These elevators are engineered to withstand frequent use, impact from carts or pallets, and significant weight loads. Their primary role is not convenience for people, but reliability for logistics, manufacturing, storage, and service workflows. In many commercial and industrial buildings, freight elevators are a core part of the internal transportation system.

Industries That Rely on Freight Elevators

Freight elevators are used across a wide range of industries, each with specific operational demands. Their flexibility in size, load capacity, and control systems allows them to be adapted to different environments. Understanding where they are most commonly used helps clarify their primary function.

Manufacturing and Industrial Facilities

In manufacturing plants, freight elevators move raw materials, semi-finished components, and finished products between production levels. Multi-story factories often depend on these elevators to maintain workflow efficiency, reduce manual handling, and prevent bottlenecks in production lines.

Warehouses and Distribution Centers

Warehouses use freight elevators to transfer palletized goods between storage floors. These elevators are designed to accommodate forklifts, pallet jacks, and heavy carts, enabling smooth vertical logistics in high-density storage environments.

Commercial Buildings and Retail Spaces

In shopping malls, hotels, and office towers, freight elevators are used for back-of-house operations. They transport merchandise, housekeeping supplies, furniture, and maintenance equipment without interfering with passenger traffic.

Types of Loads Transported by Freight Elevators

The primary use of freight elevators is defined by the types of loads they are built to carry. These loads are often oversized, heavy, or impractical for passenger elevators. Freight elevators are reinforced to handle both static weight and dynamic forces during loading and unloading.

- Palletized goods and bulk materials

- Industrial machinery and spare parts

- Furniture, appliances, and building materials

- Service carts, trolleys, and maintenance equipment

Because these loads vary in shape and handling method, freight elevators often feature wide doors, high ceilings, and rugged interior finishes that resist dents, scratches, and wear.

How Freight Elevators Support Operational Efficiency

One of the primary reasons freight elevators are used is to improve efficiency in vertical material movement. Without them, businesses would rely on ramps, manual lifting, or external hoists, all of which increase labor costs and safety risks.

Freight elevators streamline internal logistics by reducing travel time between floors, minimizing handling steps, and allowing staff to focus on core tasks. In high-volume operations, this efficiency directly impacts productivity and turnaround times.

Reducing Manual Labor

By mechanizing vertical transport, freight elevators significantly reduce the need for manual lifting. This lowers the risk of workplace injuries and helps companies comply with occupational safety standards.

Maintaining Workflow Continuity

In facilities with continuous operations, freight elevators ensure that materials are delivered where needed without delays. Dedicated freight systems prevent congestion that could occur if passenger elevators were used instead.

Differences Between Freight and Passenger Elevators

Understanding what freight elevators are primarily used for also involves knowing how they differ from passenger elevators. These differences reflect their intended function rather than aesthetic considerations.

| Design Focus | Freight Elevators | Passenger Elevators |

| Primary Use | Goods and materials | People |

| Load Capacity | Very high | Moderate |

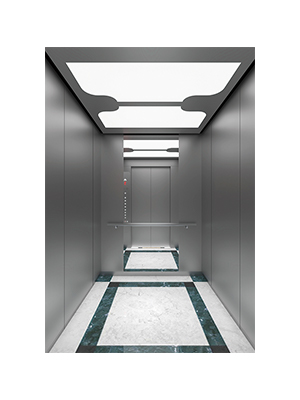

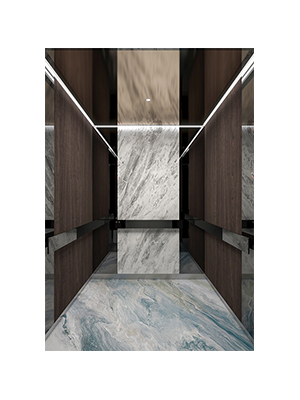

| Interior Finish | Rugged, industrial | Decorative, comfort-oriented |

Safety and Control in Freight Elevator Usage

Another primary use of freight elevators is to provide a safer alternative for transporting heavy items vertically. They are equipped with features that support controlled loading, stable movement, and secure stopping accuracy.

Operators often use constant-pressure controls, meaning the elevator only moves while a button is held down. This allows precise positioning during loading and unloading, especially when handling bulky or unstable items.

Freight Elevators in Modern Building Design

As buildings become taller and more multifunctional, freight elevators play an increasingly important role in design planning. Architects and engineers integrate them into service cores to support logistics without affecting public areas.

In mixed-use developments, freight elevators enable efficient coexistence of retail, office, residential, and service functions. Their primary use remains the same: reliable vertical transport of goods that keeps the entire building running smoothly.

Why Freight Elevators Are Essential for Business Operations

Ultimately, freight elevators are primarily used to support the backbone of business operations. From moving inventory to supporting maintenance tasks, they ensure that goods reach the right place at the right time.

For businesses that handle heavy or frequent material movement, freight elevators are not a luxury but a necessity. Their durability, capacity, and functional design make them indispensable in environments where efficiency and safety are critical.