In modern construction and industrial production, elevators are not only a tool for people to pass through, but also a key equipment for cargo transportation. Among them, freight elevators, as vertical transportation equipment specifically used to carry cargo rather than passengers, play an irreplaceable role in factories, warehouses, shopping malls, hospitals, construction sites and other places.

High load capacity

The rated load of freight elevators usually ranges from 1 ton to 5 tons, or even higher, which can meet the vertical transportation needs of heavy materials in large factories, storage centers and construction sites.

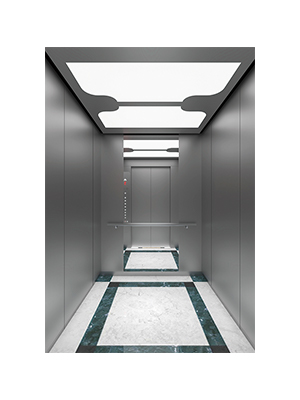

Strong and durable structural design

The car is made of high-strength steel and the floor is thickened to withstand the impact of heavy objects and long-term wear. At the same time, the door body is mostly double-leaf push-pull or vertical sliding type, which is convenient for forklifts or other handling equipment to enter and exit.

Flexible operation and strong adaptability

The freight elevator can realize multi-point control of the floor station, support manual or automatic door opening, and can be configured with remote control, pit passage, explosion-proof device and other functional modules according to user needs, suitable for different industry environments.

High safety

Although mainly used for cargo transportation, modern freight elevators are still equipped with multiple safety protection mechanisms, such as overload alarms, emergency stop buttons, speed limiters, buffers, etc., to ensure safe operation under various working conditions.

Freight Elevators are widely used in the following fields:

Manufacturing factories: used for efficient circulation of raw materials, semi-finished products and finished products between different floors.

Commercial buildings and shopping centers: assist merchants in moving goods, display racks, equipment, etc. to improve operational efficiency.

Hospitals and laboratories: used to transport precision items such as medicines, medical equipment, and laboratory equipment.

Construction projects: temporary freight elevators are often installed at construction sites to transport building materials, tools and equipment to improve construction progress.

Logistics and warehousing centers: cooperate with automated warehousing systems to achieve rapid dispatch of goods in three-dimensional space.

According to the drive mode, freight elevators can be divided into three types: traction type, hydraulic type and gear rack type. Among them:

Traction freight elevator: energy-saving and efficient, suitable for medium and high-rise buildings;

Hydraulic freight elevator: simple structure, suitable for low-rise factories and lifting platforms;

Rack and pinion freight elevator: construction elevators commonly seen on construction sites, suitable for outdoor operations.

With the development of intelligent manufacturing and Industry 4.0, future Freight Elevators are evolving towards intelligence and automation. For example, after integrating IoT technology, freight elevators can realize functions such as remote monitoring, fault warning, and intelligent scheduling; some high-end systems also support working with AGV (automatic guided vehicles) to create a fully automated logistics and transportation system.

Although Freight Elevators are not as well-known as passenger elevators, they are indispensable "behind-the-scenes heroes" in modern industrial and commercial operations. They silently undertake heavy transportation tasks, ensuring the smoothness of production processes and the improvement of logistics efficiency. In the future, with the advancement of technology and the expansion of application scenarios, freight elevators will continue to evolve and become an important link between physical space and the intelligent world, providing more efficient, safe and sustainable solutions for the global manufacturing and logistics systems.